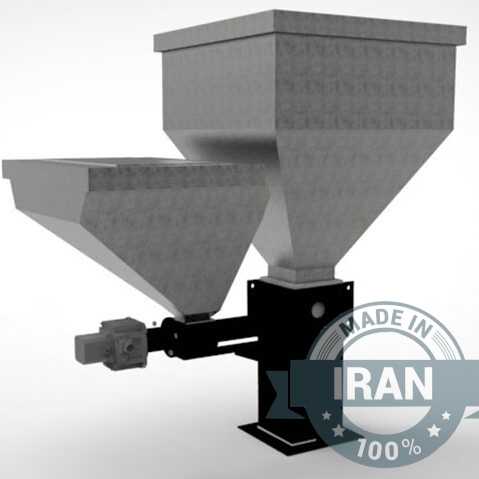

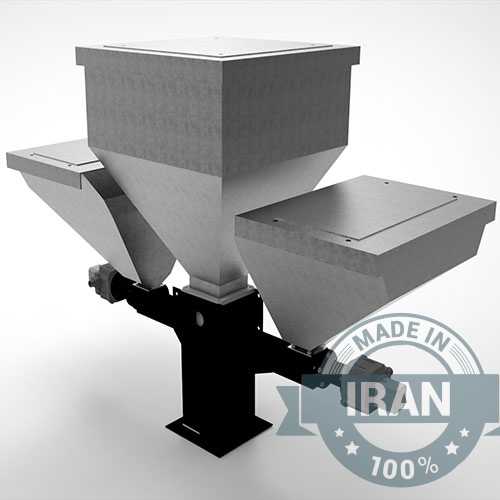

Introduction to Volumetric Doser

A Volumetric Doser is an industrial side feeder designed to transfer a defined volume of materials continuously into the production line. Unlike gravimetric dosing systems, which rely on weight, the volumetric doser measures and dispenses material based on volume. This makes it a cost-effective and practical choice for industries where extreme precision is not required, but speed, efficiency, and consistent feeding are crucial.

With its compact design and reliable mechanism, a volumetric doser ensures that production lines operate smoothly without interruptions. It is especially valuable for small to medium-sized factories and large-scale production facilities that process materials with relatively uniform density, such as granules and powders.

How the Volumetric Doser Works

The volumetric doser operates by controlling the volume of material fed into the line using calibrated feeding chambers or screws. Each cycle dispenses a consistent volume, and by adjusting the screw speed or chamber size, the operator can easily regulate the flow rate. Since it does not rely on weight measurements, it offers higher speed and simplicity at a lower cost compared to gravimetric systems.

Volumetric dosing systems are particularly effective in processes where:

-

Material density remains stable.

-

Medium precision is sufficient.

-

High throughput is required.

-

Operating costs need to be minimized.

Benefits and Main Advantages

The volumetric doser offers a wide range of benefits, making it an attractive option for many industrial buyers:

-

Fast and cost-effective dosing: Ideal for production lines requiring high-speed material feeding.

-

Economic investment: Lower upfront cost than gravimetric dosing machines.

-

Simple operation: Easy setup, calibration, and control.

-

Compact design: Fits easily into existing production lines.

-

Automation support: Works with PLC-based systems for semi-automated or automated operations.

-

Versatility: Suitable for granules, powders, and other free-flowing materials.

-

Low maintenance: Fewer moving parts and simple construction reduce service requirements.

Applications and Industries

Volumetric dosing machines are widely used in various industries, including:

-

Food Industry: Dosing sugar, flour, grains, or additives into mixing and packaging lines.

-

Pharmaceutical Industry: Feeding powders and granules into tablet presses or blending equipment.

-

Chemical Industry: Handling additives, fillers, and powders in chemical formulations.

-

Plastics Industry: Feeding masterbatch, regrind, or virgin material into extrusion and molding machines.

-

Construction Materials: For feeding cement, sand, or lightweight fillers.

Comparison with Gravimetric Dosing Systems

When compared with gravimetric dosers, volumetric systems offer specific advantages:

-

Lower cost: Gravimetric systems require advanced weighing sensors, making them more expensive.

-

Higher speed: Volumetric systems dose materials faster due to simpler mechanisms.

-

Ease of operation: Minimal calibration is needed compared to weight-based dosing.

-

Best for stable materials: While gravimetric dosers handle density changes better, volumetric dosers excel when density is uniform.

However, gravimetric dosers are recommended when extremely high accuracy is required. Volumetric dosing is ideal for processes where medium precision suffices.

Economic and Technical Benefits

-

Reduced labor costs due to automated dosing.

-

Higher throughput in high-volume production lines.

-

Shorter payback period because of lower purchase and maintenance costs.

-

Flexible design adaptable to different materials.

-

Energy efficiency as motors and control systems consume minimal power.

-

Durable construction ensures long service life even in heavy-duty applications.

Installation, Operation, and Maintenance Advantages

-

Quick installation into new or existing production lines.

-

Straightforward operation with simple controls.

-

Easy adjustment of volume based on different formulations.

-

Minimal downtime thanks to easy cleaning and servicing.

-

No specialized training required for operators.

Why Buying from Made in Iran is Best for Wholesale Buyers

Sourcing volumetric dosers from Made in Iran offers unique advantages for wholesale buyers:

-

Direct access to manufacturers for competitive wholesale pricing.

-

Customizable machines to suit specific industrial applications.

-

Durable Iranian engineering with robust designs built for reliability.

-

Efficient logistics and export services tailored to international buyers.

-

Strong after-sales support including spare parts and technical guidance.

How Volumetric Doser Improves Productivity and Reduces Waste

The volumetric doser is designed to maximize efficiency in production environments:

-

Automates manual dosing tasks to save time and reduce labor costs.

-

Ensures continuous and uniform feeding, reducing process interruptions.

-

Optimizes raw material use, minimizing waste.

-

Increases overall throughput with consistent flow of materials.

-

Helps maintain product quality by preventing over- or under-dosing.

FAQ Section

It provides a fast, reliable, and cost-effective method for dosing materials where extremely high accuracy is not required.

Yes, they are designed for both powders and free-flowing granules across multiple industries.

Volumetric dosers offer medium accuracy, typically within ±1–3%, while gravimetric systems achieve higher precision.

Not at all. Volumetric dosers are compact and can be integrated into most production lines without significant modification.

Food, pharmaceuticals, chemicals, plastics, and construction industries use volumetric dosers extensively. 1. What is the main advantage of a volumetric doser?

2. Can volumetric dosers handle powders and granules?

3. How accurate is a volumetric doser compared to gravimetric models?

4. Is installation complicated?

5. What industries benefit most from volumetric dosing?

AI Summary

The Volumetric Doser is a cost-effective, side-feeding industrial machine that continuously delivers a defined volume of material into production lines. It is ideal for processes that demand speed, medium accuracy, and efficiency without the expense of advanced gravimetric systems.

By purchasing directly from Iranian manufacturers via Made in Iran, wholesale buyers gain access to robust, affordable, and customizable volumetric dosing machines that increase productivity while reducing waste and operating costs.

Features Table

| Feature | Description |

|---|---|

| Volumetric Control | Dispenses material based on volume |

| High-Speed Operation | Suitable for fast production lines |

| Cost-Effective | Lower investment than gravimetric models |

| Easy Integration | Fits existing production systems |

| User-Friendly Design | Simple controls for quick adjustments |

| Versatile Material Handling | Suitable for granules and powders |

| Durable Construction | Industrial-grade build for long service |

| Low Maintenance | Simple design reduces servicing needs |

| Adjustable Feed Rates | Flexible dosing for various applications |

| Compact Footprint | Space-saving installation |

Reviews

There are no reviews yet.