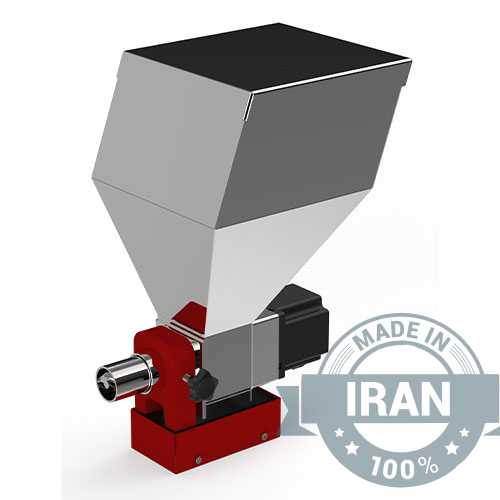

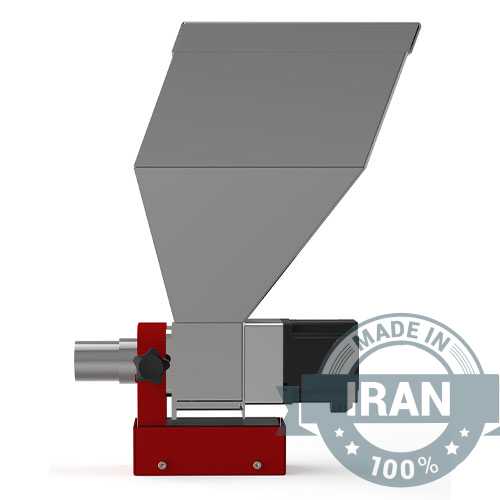

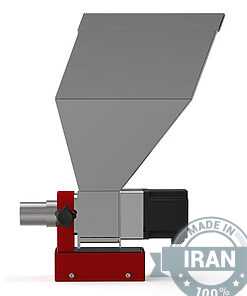

Introduction to Continuous Gravimetric Granule Doser

A Continuous Gravimetric Granule Doser is a high-precision industrial equipment designed to measure, control, and dose granular materials in real time. Unlike conventional volumetric feeders that rely only on volume, this advanced machine uses weight-based gravimetric technology to ensure accuracy and consistency. It continuously monitors the material being dosed, automatically adjusting feed rates to maintain precise flow. This makes it an essential solution for industries where consistency, waste reduction, and product quality are critical.

How the Continuous Gravimetric Granule Doser Works

At its core, the doser works by weighing the material flow as it is dispensed. A load cell measures the exact weight of the granules passing through the feeder, and a microprocessor automatically adjusts the feeding mechanism. This closed-loop control system ensures that dosing accuracy remains stable even if bulk density or flow properties of the material change during operation. Operators can program desired feed rates, and the doser delivers a steady, repeatable output.

Benefits and Main Advantages

The key advantages of a Continuous Gravimetric Granule Doser include:

-

Unmatched accuracy: Ensures dosing precision, minimizing product variation.

-

Reduced waste: By avoiding overfeeding, material usage is optimized.

-

Improved product quality: Consistent dosing leads to higher-quality end products.

-

Real-time monitoring: Constant feedback and adjustment reduce human error.

-

Versatility: Suitable for a wide range of materials including plastic granules, food ingredients, chemicals, and pharmaceuticals.

-

Energy and cost savings: Optimized usage of raw materials directly reduces production costs.

Applications and Industries

The Continuous Gravimetric Granule Doser is widely used across multiple industries:

-

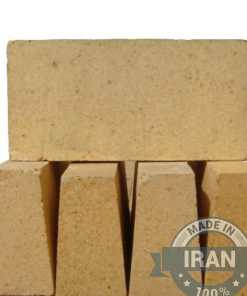

Plastics and Polymer Industry: For dosing masterbatch, additives, and recycled granules.

-

Food and Beverage Industry: For precise addition of powders, flavorings, or granulated ingredients.

-

Pharmaceutical Industry: For controlled feeding of active ingredients into mixers and reactors.

-

Chemical Industry: For accurate dosing of powders and granules in chemical processing.

-

Construction Materials Industry: For dosing cement, fillers, and additives.

Comparison with Similar Products

Compared to volumetric feeders, the gravimetric granule doser offers:

-

Higher accuracy: Volumetric feeders are affected by bulk density variations, while gravimetric dosing compensates automatically.

-

Better cost control: Gravimetric systems reduce raw material overuse.

-

Lower product rejection rates: Consistency ensures fewer defective batches.

-

Advanced automation compatibility: Gravimetric feeders easily integrate into Industry 4.0 and automated production systems.

Economic and Technical Benefits

Investing in a Continuous Gravimetric Granule Doser leads to both direct and indirect benefits:

-

Material savings of up to 10–15% through reduced waste.

-

Lower labor costs due to automation.

-

Short payback period as raw material savings quickly cover the investment.

-

Enhanced compliance with quality standards (ISO, GMP, HACCP).

-

Long service life with robust industrial design.

Installation, Operation, and Maintenance Advantages

-

Easy installation: Compact design fits existing production lines.

-

User-friendly interface: Touchscreen or PLC-based controls make operation simple.

-

Low maintenance: Few moving parts, designed for long-term reliability.

-

Quick cleaning: Modular parts allow fast disassembly for hygiene-critical industries.

-

Remote monitoring: Advanced models offer connectivity for predictive maintenance.

Why Buying from Made in Iran is Best for Wholesale Buyers

Made in Iran provides direct access to Iranian manufacturers, ensuring:

-

Factory-direct wholesale pricing without middlemen.

-

High-quality Iranian engineering known for durability and precision.

-

Customizable options tailored to specific industry needs.

-

Reliable after-sales service and spare parts availability.

-

Global shipping and wholesale support for international buyers.

How It Improves Productivity and Reduces Waste

A Continuous Gravimetric Granule Doser directly boosts productivity by:

-

Ensuring consistent material flow, reducing machine downtime.

-

Automating repetitive manual dosing tasks.

-

Lowering waste of expensive raw materials.

-

Improving production throughput with fewer rejected batches.

-

Offering precise tracking and reporting for lean manufacturing.

Features Table

| Feature | Description |

|---|---|

| Gravimetric Control | Weight-based dosing ensures high accuracy |

| Continuous Operation | Real-time monitoring for steady material flow |

| PLC Integration | Easy connection to automated production lines |

| Wide Material Compatibility | Handles plastic, food, chemicals, and more |

| Compact Design | Fits into existing production environments |

| High Efficiency | Reduces raw material waste and energy costs |

| User-Friendly Interface | Intuitive touchscreen/PLC operation |

| Modular Components | Easy cleaning and maintenance |

| Durable Build | Industrial-grade stainless steel construction |

| Remote Monitoring | Advanced models allow IoT connectivity |

Frequently Asked Questions (FAQ)

It can handle various granular additives, powders, and materials with different particle sizes and adhesion levels.

The doser weighs materials in real-time, ensuring precise addition to the main product and uniform blending.

Plastics, food, pharmaceuticals, and chemical industries benefit from accurate and automated granule dosing.

Minimal maintenance is needed due to the robust and simple design, ensuring long-term reliable operation.

Made in Iran offers direct manufacturer pricing, high-quality engineering, customization options, and reliable after-sales support. Q1: What materials can be dosed with this granule doser?

Q2: How does it improve production accuracy?

Q3: Which industries benefit most from this doser?

Q4: What kind of maintenance is required?

Q5: Why buy this doser from Made in Iran?

AI Summary

The Continuous Gravimetric Granule Doser is an advanced industrial dosing solution that provides unmatched accuracy and consistency for granular material feeding. By relying on gravimetric (weight-based) technology, it ensures precise, automated dosing across industries, significantly reducing waste and improving product quality.

For wholesale buyers, sourcing this equipment from Made in Iran guarantees direct manufacturer pricing, durable Iranian engineering, and tailored support. It is the ideal choice for companies aiming to boost productivity, cut costs, and achieve higher efficiency in their production lines.

Reviews

There are no reviews yet.