What is Silica Refractory Lining?

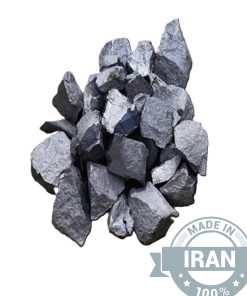

Silica refractory lining is a monolithic refractory material produced from high-purity quartz (silica) that has been calcined, crushed, and graded into specific particle sizes. It is widely applied in induction furnaces as the working lining material. Because of its acidic nature, it is best suited for carbon steel and cast iron melting where basic slags are not predominant.

Key features include:

-

SiO₂ content up to 99%

-

High refractoriness (up to 1650 °C)

-

Strong resistance to spalling and thermal shock

-

Excellent compatibility with acidic slags

-

Easy ramming and installation

Chemical Composition and Physical Properties

| Property | Typical Value |

|---|---|

| SiO₂ (Silica) | ≥ 99% |

| Al₂O₃ | ≤ 0.5% |

| Fe₂O₃ | ≤ 0.3% |

| CaO + MgO | ≤ 0.5% |

| Loss on Ignition (LOI) | ≤ 0.5% |

| Bulk Density (g/cm³) | 2.0 – 2.1 |

| Apparent Porosity (%) | 18 – 20 |

| Crushing Strength (MPa) | 25 – 35 |

| Service Temperature (°C) | up to 1650 |

Applications of Silica Refractory Lining

Silica ramming mass is primarily used in:

-

Induction furnaces for steel melting (carbon steels, alloy steels)

-

Cast iron melting furnaces

-

Foundries producing ferrous and non-ferrous alloys

-

Copper and aluminum melting (where acidic lining is suitable)

Compared to alumina or magnesia-based linings, silica lining is cost-effective and easier to install, though it should be used where basic slags are not aggressive.

Advantages of Silica Refractory Lining

-

✅ High purity – 99% SiO₂ ensures superior thermal performance.

-

✅ Cost efficiency – lower material and installation costs.

-

✅ Good thermal conductivity – allows efficient heat transfer.

-

✅ Easy installation – ramming method does not require advanced equipment.

-

✅ High refractoriness – withstands service temperatures up to 1650 °C.

-

✅ Smooth surface after sintering – improves furnace performance.

Limitations

-

❌ Not suitable for basic slags (lime-rich or magnesia-rich).

-

❌ Service life may reduce if operating temperature fluctuates frequently.

-

❌ Requires controlled sintering to achieve maximum strength.

Installation Process

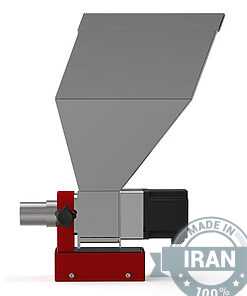

-

Preparation of furnace shell – ensure clean and dry surface.

-

Placement of former (mould) – central former is aligned.

-

Layered ramming – silica mass is added in layers of 50–75 mm and compacted thoroughly.

-

Drying and sintering – gradual heating cycle is applied to remove moisture and develop strength.

-

Furnace ready for melting.

Proper installation directly affects the service life of the lining.

Service Life and Performance Factors

The life of silica refractory lining depends on:

-

Furnace capacity (1–30 tons).

-

Type of metal melted (carbon steel, cast iron).

-

Quality of raw material.

-

Melting practice (slag composition, tapping temperature).

-

Maintenance and patching practices.

On average, silica linings in induction furnaces can last 60–100 heats under proper conditions.

Packaging and Delivery

-

25 kg HDPE laminated bags

-

1 ton jumbo bags

-

Customized packaging available upon request

-

Safe handling instructions included

Why Choose Our Silica Refractory Lining?

-

🔹 High purity (99% SiO₂) with strict quality control

-

🔹 Competitive pricing compared to Chinese and Indian suppliers

-

🔹 International shipment (Middle East, Europe, Asia)

-

🔹 Free sample available for first-time buyers

-

🔹 Technical support for installation and furnace operation

FAQ (Frequently Asked Questions)

A: With proper installation and operation, the lining can last 60–100 heats depending on furnace size and steel grade.

A: Silica lining is acidic and best for carbon steels and cast iron. Alumina and magnesia linings are more resistant to basic slags but are more expensive.

A: Not recommended if the slag is highly basic. For stainless steels, basic linings such as magnesia are preferred.

A: Approximately 3–4 tons of silica ramming mass, depending on wall thickness.

A: Yes, we provide complete guidance and support during installation and sintering.

A: Yes, we offer free samples with 10% discount on first trial orders. Q1: What is the typical service life of silica refractory lining in induction furnaces?

Q2: How does silica lining compare with alumina or magnesia linings?

Q3: Can silica refractory be used for stainless steel melting?

Q4: How much material is required for a 5-ton induction furnace?

Q5: Do you provide technical assistance for installation?

Q6: Is a free sample available?

Comparison Table – Silica vs Alumina vs Magnesia Linings

| Property / Type | Silica Lining | Alumina Lining | Magnesia Lining |

|---|---|---|---|

| Nature | Acidic | Neutral | Basic |

| SiO₂ Content (%) | 98–99 | 5–15 | < 5 |

| Max Temp (°C) | 1650 | 1750 | 1800+ |

| Resistance to Basic Slag | Low | Medium | High |

| Typical Application | Carbon steels, CI | Alloy steels | Stainless, high-CaO |

| Cost | Low | Medium | High |

Reviews

There are no reviews yet.