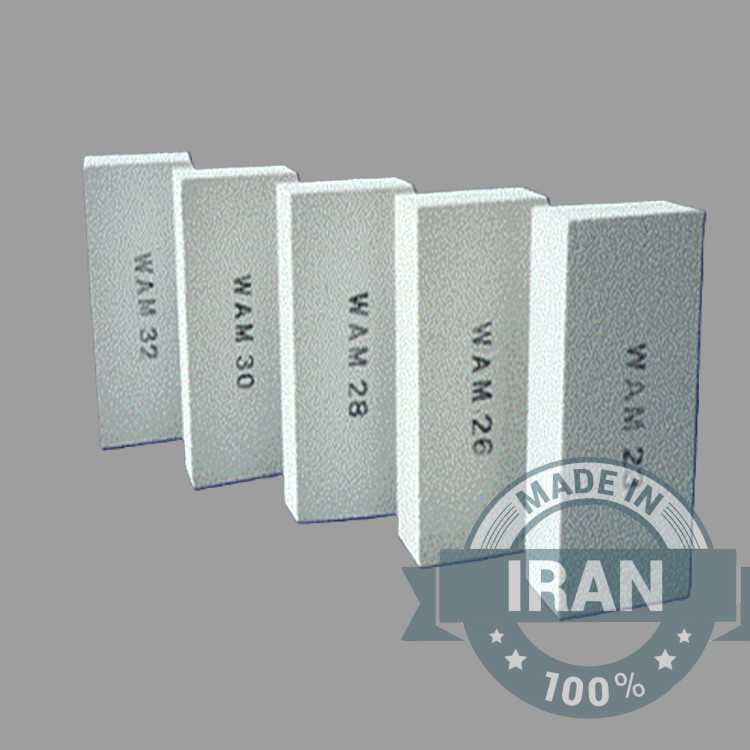

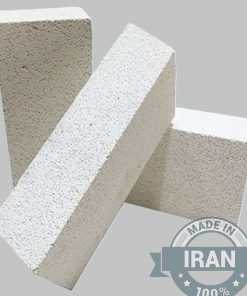

Refractory Insulating Bricks, also known as Insulating Fire Bricks (IFB), are engineered for high-performance thermal insulation in industrial furnaces, kilns, and ovens. Manufactured from high-purity refractory materials like silica or low-iron clays, these bricks feature exceptional porosity, resulting in low density and minimal heat transfer. This unique structure ensures reduced energy loss, lower fuel costs, and faster heating cycles, making them a preferred choice for industries seeking efficiency and sustainability.

The high porosity is achieved through advanced production techniques, such as the addition of organic materials like sawdust or lightweight diatomite, which burn out during firing to create internal voids. These voids trap air, significantly reducing thermal conductivity and enhancing insulation. Available in grades such as 1260°C and 1450°C, these bricks cater to a wide range of temperature requirements, from tunnel kilns and rotary cement kilns to glass furnace crowns and ceramic kilns.

Designed for both hot-face and backup linings, Refractory Insulating Bricks offer versatility, with standard and custom shapes like trapezoidal or curved bricks to meet specific furnace designs. Their lightweight nature reduces the overall structural load of furnaces, enabling thinner walls without compromising thermal performance. For applications requiring higher mechanical strength, specialized high-alumina or bubble alumina-based insulating bricks are available, offering enhanced durability and resistance to corrosive environments.

Sourced directly from trusted manufacturers, our Refractory Insulating Bricks meet stringent quality standards, ensuring consistent performance in demanding industrial settings. Whether for large-scale furnace construction or maintenance, these bricks are a cost-effective solution for wholesalers and distributors targeting energy-efficient, high-quality refractory materials.

FAQ for Refractory Insulating Bricks:

These bricks are used in high-temperature environments like kilns, furnaces, and ovens for thermal insulation, reducing heat loss and improving energy efficiency. They are suitable for hot-face linings, backup insulation, and specialized applications like glass and cement production.

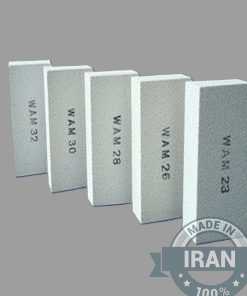

Our bricks are available in grades such as 26 (1260°C) and 28 (1450°C), with custom options for higher-temperature or high-strength applications, including bubble alumina-based bricks.

Yes, we offer standard and non-standard shapes, including trapezoidal, wedge, or curved bricks, tailored to specific furnace designs and client requirements.

Their high porosity and low thermal conductivity minimize heat loss, reduce fuel consumption, and allow faster heating cycles, optimizing operational costs.

Lead times depend on order size and customization. Contact our team for precise timelines and to ensure seamless delivery for your project. What are Refractory Insulating Bricks used for?

What grades are available?

Can the bricks be customized?

How do these bricks improve energy efficiency?

What is the lead time for bulk orders?

Product Specifications Table:

|

Feature |

Specification |

|---|---|

|

Material Composition |

Silica, low-iron clay, or high-alumina (bubble alumina for high-strength grades) |

|

Temperature Rating |

1260°C (Grade 26), 1450°C (Grade 28), custom high-temperature options available |

|

Thermal Conductivity |

Low (0.2–0.5 W/m·K, depending on grade) |

|

Density |

Lightweight (0.6–1.2 g/cm³) |

|

Porosity |

High (up to 70%), ensuring excellent insulation |

|

Standard Shapes |

Rectangular, trapezoidal, wedge, curved |

|

Compressive Strength |

1.5–5 MPa (standard), up to 10 MPa for high-strength grades |

|

Applications |

Kilns, furnaces, ovens, glass production, cement plants, ceramic industries |

|

Customization |

Available for size, shape, and material composition |

Elevate your industrial operations with premium Refractory Insulating Bricks, designed for energy efficiency and durability. Contact our team today to request a quote, explore customization options, or schedule a consultation. Source directly from trusted manufacturers and secure your bulk supply for global projects. Act now to optimize your furnace performance and reduce operational costs!

Reviews

There are no reviews yet.