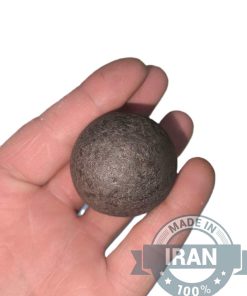

Ferromolybdenum, an essential ferroalloy composed of iron and molybdenum (typically 60-75% Mo), is a cornerstone in the production of high-strength, corrosion-resistant alloys. This versatile material is critical for industries requiring robust, durable metals, such as stainless steel, tool steel, and high-speed steel manufacturing. By incorporating ferromolybdenum, alloys gain enhanced hardness, weldability, and resistance to wear and corrosion, making it indispensable for applications in automotive, aerospace, energy, and heavy machinery sectors.

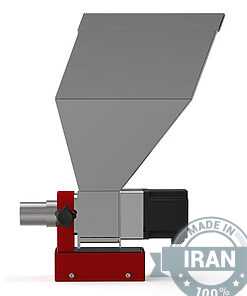

Sourced directly from trusted producers, our ferromolybdenum is manufactured through advanced aluminothermic or silicothermic reduction processes, ensuring consistent quality and high molybdenum recovery rates (up to 95% in optimal conditions). Available in multiple grades, including Ferromolybdenum 60-65% and 55-60%, as well as export-grade variants, this product meets stringent international standards, making it a preferred choice for bulk buyers in global markets.

Whether used in heat-resistant superalloys for turbine components, corrosion-resistant stainless steels for chemical processing, or high-strength structural steels for construction, ferromolybdenum delivers unmatched performance. Its ability to improve creep resistance, reduce brittleness at high temperatures, and enhance weldability ensures superior results in demanding environments. Packaged in durable containers for safe international shipping, our ferromolybdenum is tailored for wholesale buyers seeking reliable, high-quality materials for large-scale production.

FAQ for Ferromolybdenum

Ferromolybdenum is primarily used to enhance the properties of stainless steels, alloy steels, and superalloys. It improves hardness, corrosion resistance, and weldability, making it ideal for applications in automotive, aerospace, energy, and construction industries.

We offer Ferromolybdenum 60-65%, Ferromolybdenum 55-60%, and export-grade variants, each tailored to meet specific industrial requirements.

Ferromolybdenum is produced through aluminothermic or silicothermic reduction of molybdenum trioxide (MoO3) combined with iron, ensuring high purity and consistent quality.

Our MOQ is designed to accommodate wholesale buyers. Please contact our team for specific details based on your requirements.

Yes, ferromolybdenum enhances heat resistance and creep strength, making it ideal for high-temperature environments like boilers, turbines, and exhaust systems.

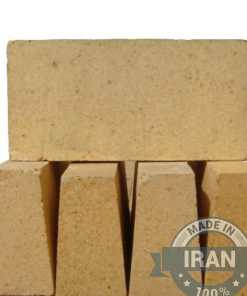

Ferromolybdenum is packaged in robust steel drums, big bags, or briquette cases to ensure safe and secure delivery for international bulk orders.

Our ferromolybdenum complies with international quality standards, including ISO certifications. Specific certifications can be provided upon request.

Ferromolybdenum offers superior hardness, corrosion resistance, and weldability, making it a cost-effective solution for producing high-performance alloys. What is ferromolybdenum used for?

What grades of ferromolybdenum are available?

How is ferromolybdenum produced?

What is the minimum order quantity (MOQ) for ferromolybdenum?

Is ferromolybdenum suitable for high-temperature applications?

How is ferromolybdenum packaged for shipping?

What certifications does your ferromolybdenum meet?

Why choose ferromolybdenum for alloy production?

Elevate your alloy production with premium ferromolybdenum sourced directly from trusted manufacturers. Contact our team at MadeInIrani.com today to request a quote, discuss bulk pricing, or explore tailored solutions for your industrial needs. Secure your supply of high-quality ferromolybdenum and gain a competitive edge in global markets!

Reviews

There are no reviews yet.