1. Executive Overview – The Essence of Marble

Marble has long stood as one of the world’s most iconic natural stones, valued for its timeless beauty, resilience, and ability to enhance spaces with elegance and sophistication. Whether you are a construction contractor, a wholesaler, or an interior designer sourcing materials for luxury projects, wholesale marble slabs and tiles remain a foundational choice for flooring, wall cladding, countertops, and architectural decoration.

At MADE IN IRANI Marketplace, we connect professional buyers and importers with verified stone suppliers offering premium-grade marble products in a range of colors, finishes, and dimensions. Every slab represents a combination of art and geology — crafted through precision cutting, surface finishing, and strict quality control to ensure uniformity, polish retention, and mechanical strength.

Our platform serves global buyers looking for bulk marble supply at competitive rates, complete documentation for export, and dependable logistics worldwide. We focus on quality, consistency, and transparency so that our partners can source confidently for large-scale commercial and residential developments.

2. Understanding Marble – Formation, Qualities, and Applications

Marble is a metamorphic rock formed from limestone through natural recrystallization under heat and pressure. Its crystalline structure gives it remarkable density and the capacity to take a high polish — properties that make it suitable for both functional and decorative use.

🔸 Typical Applications

-

Flooring: commercial buildings, villas, hotels, airports

-

Wall cladding: interior lobbies, façades, corridors

-

Countertops & vanity tops: bathrooms, kitchens, reception desks

-

Architectural decoration: staircases, columns, fountains, sculptures

-

Public projects: museums, government halls, exhibition centers

🔸 Advantages for Bulk Buyers

-

Wide availability of sizes, finishes, and colors

-

Long-term durability and resistance to compression

-

Excellent thermal performance and dimensional stability

-

Adds real-estate value through luxury aesthetics

-

Compatible with both classic and contemporary design

Marble’s high compressive strength (80–120 MPa) and low water absorption (< 0.5 %) make it a reliable stone for heavy-traffic surfaces. When properly finished and sealed, marble resists staining and remains luminous for decades, making it ideal for high-end construction and refurbishment projects.

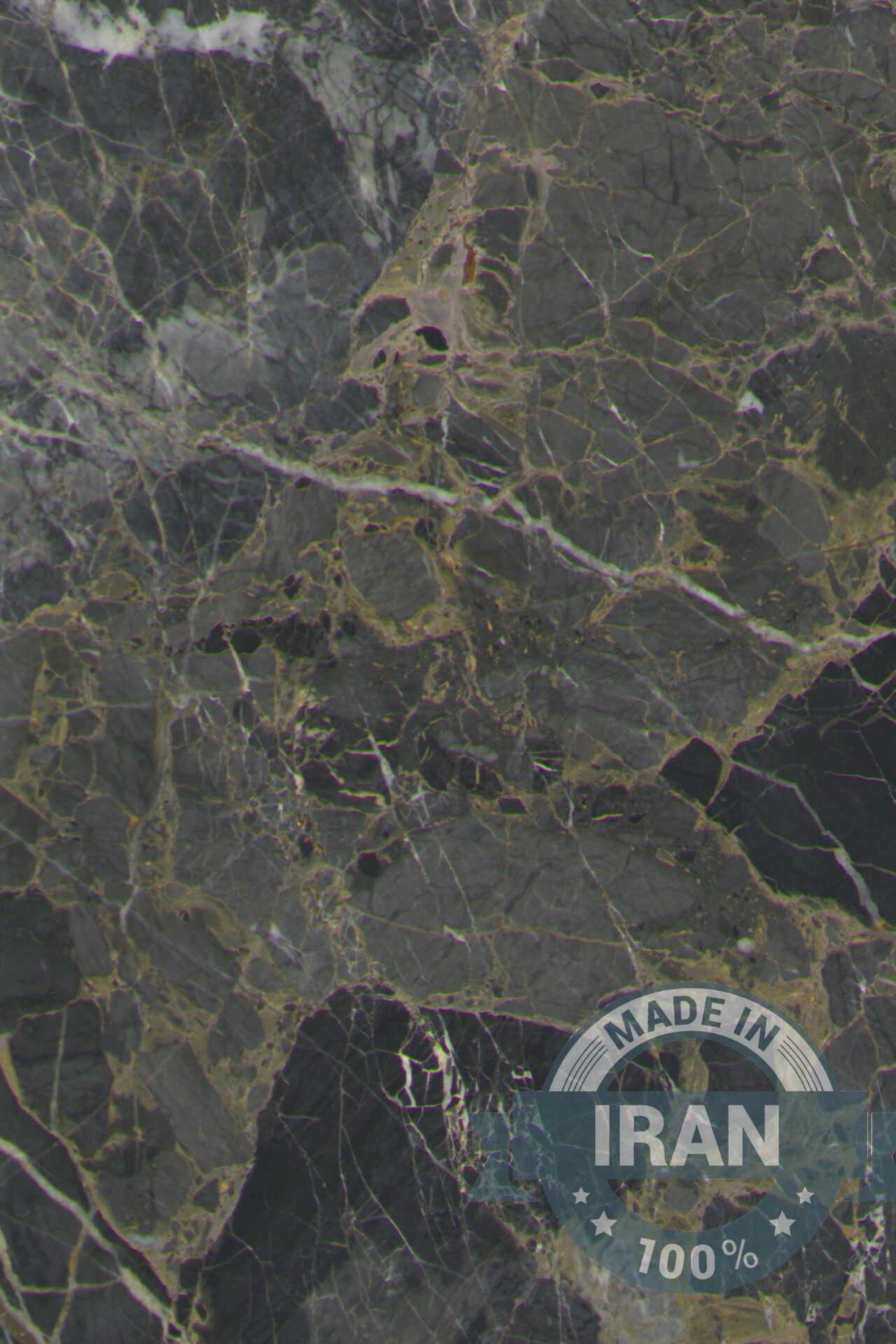

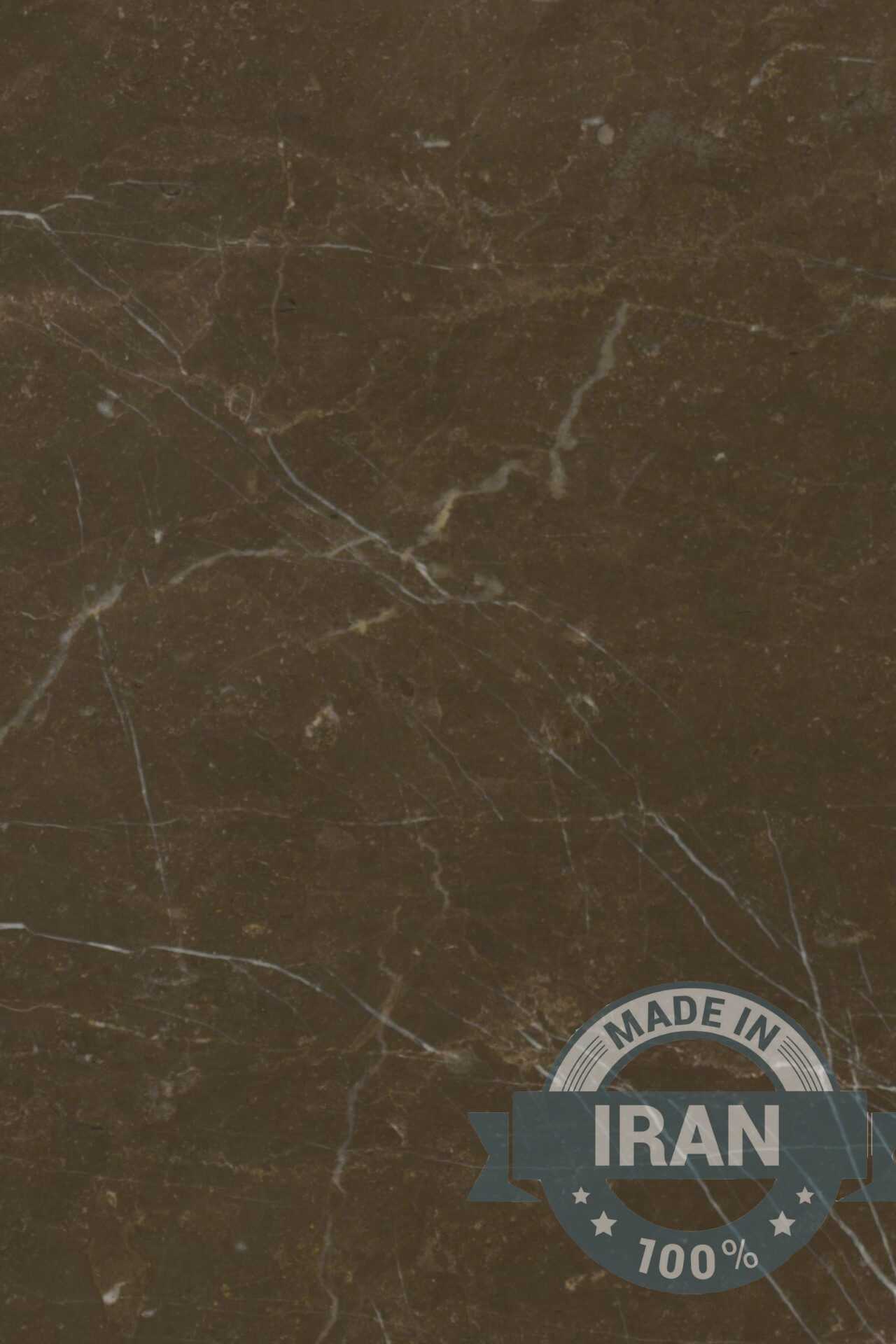

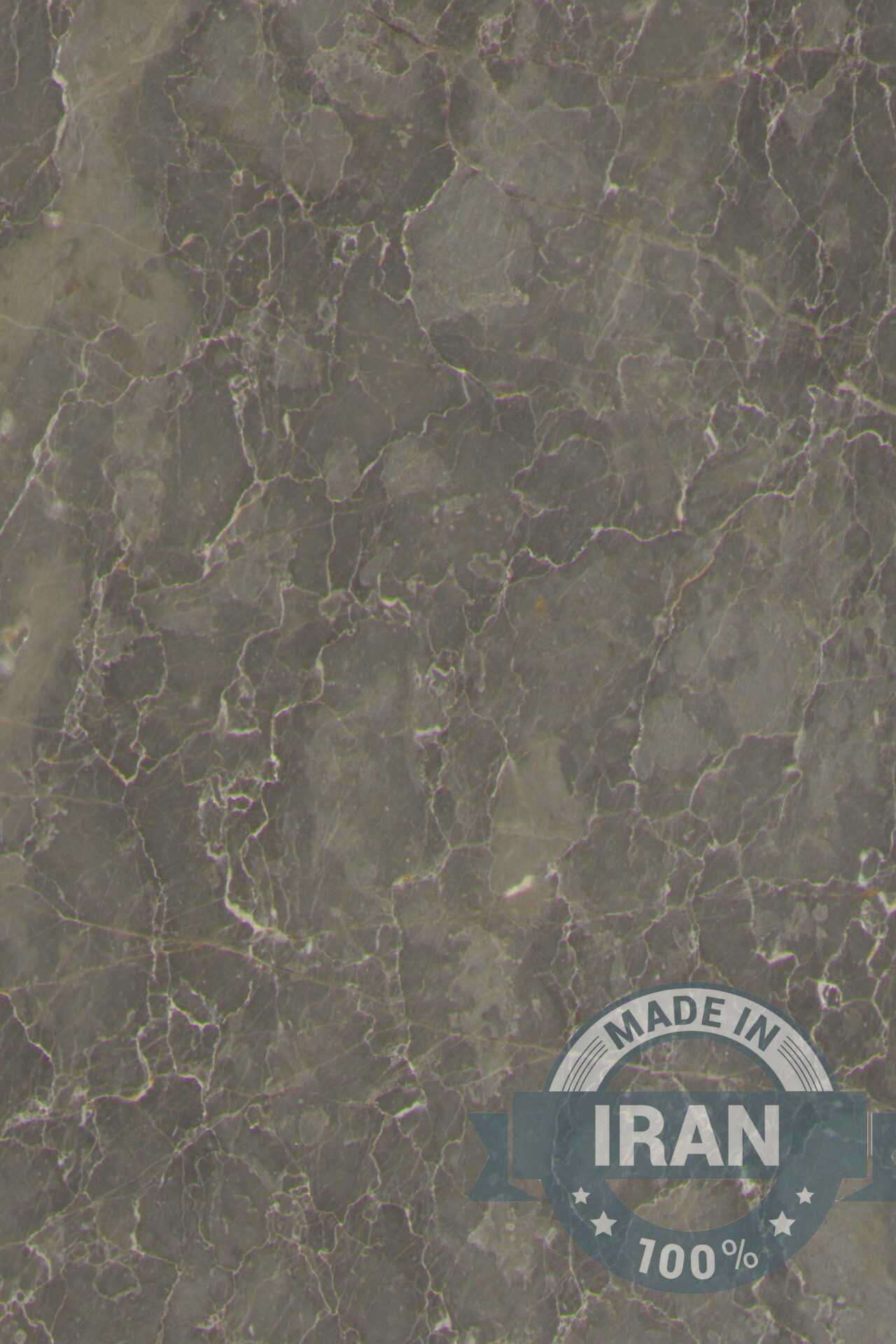

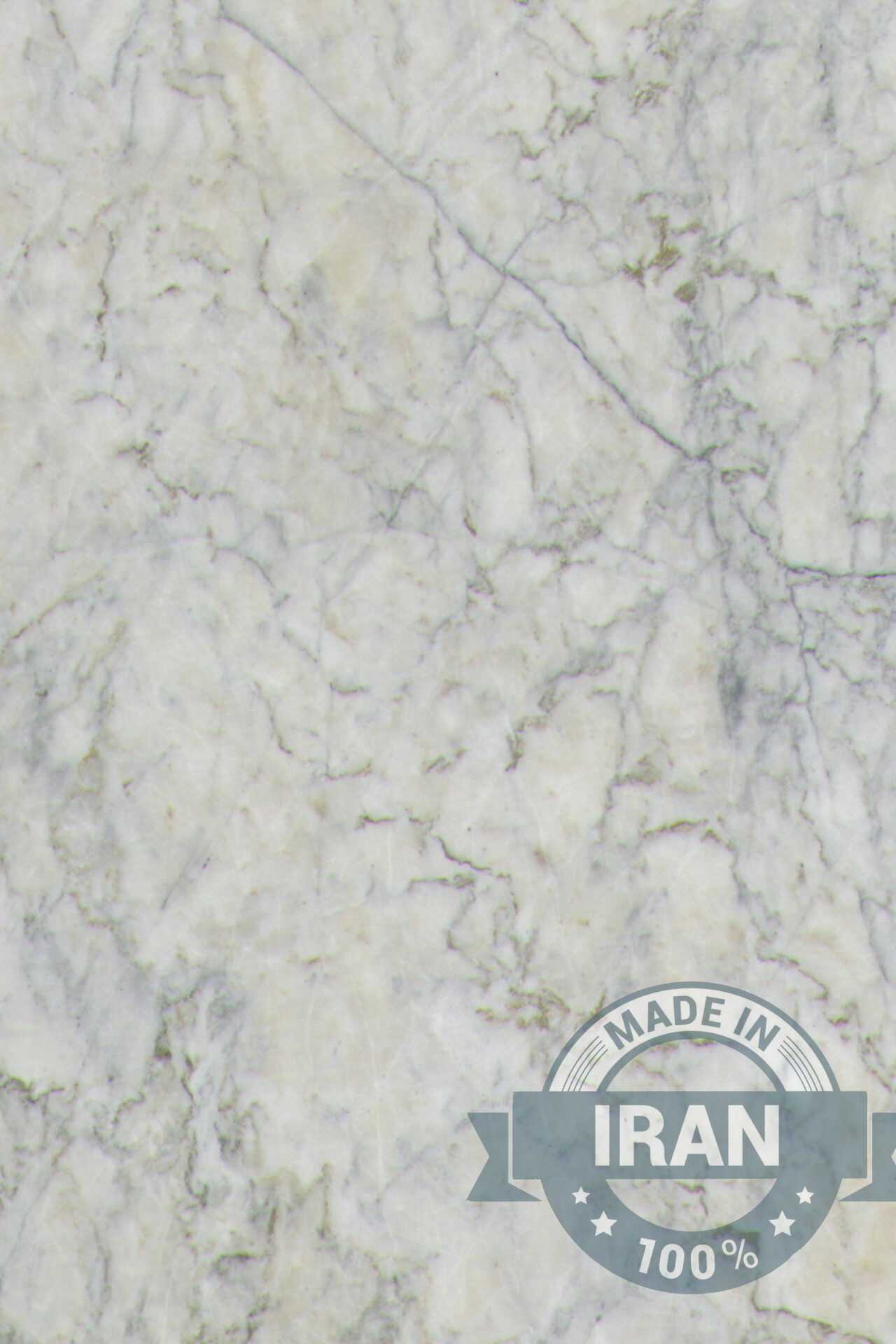

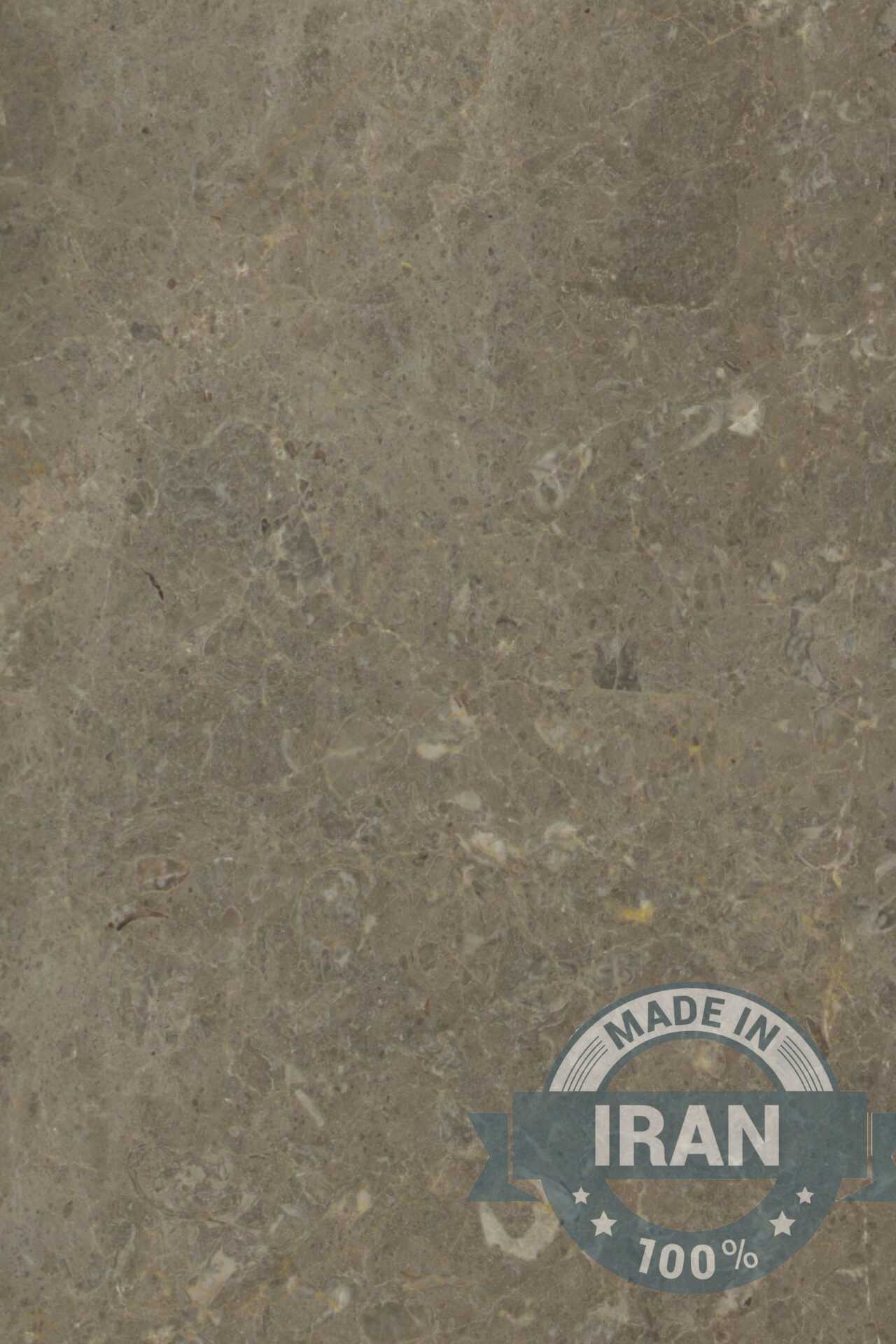

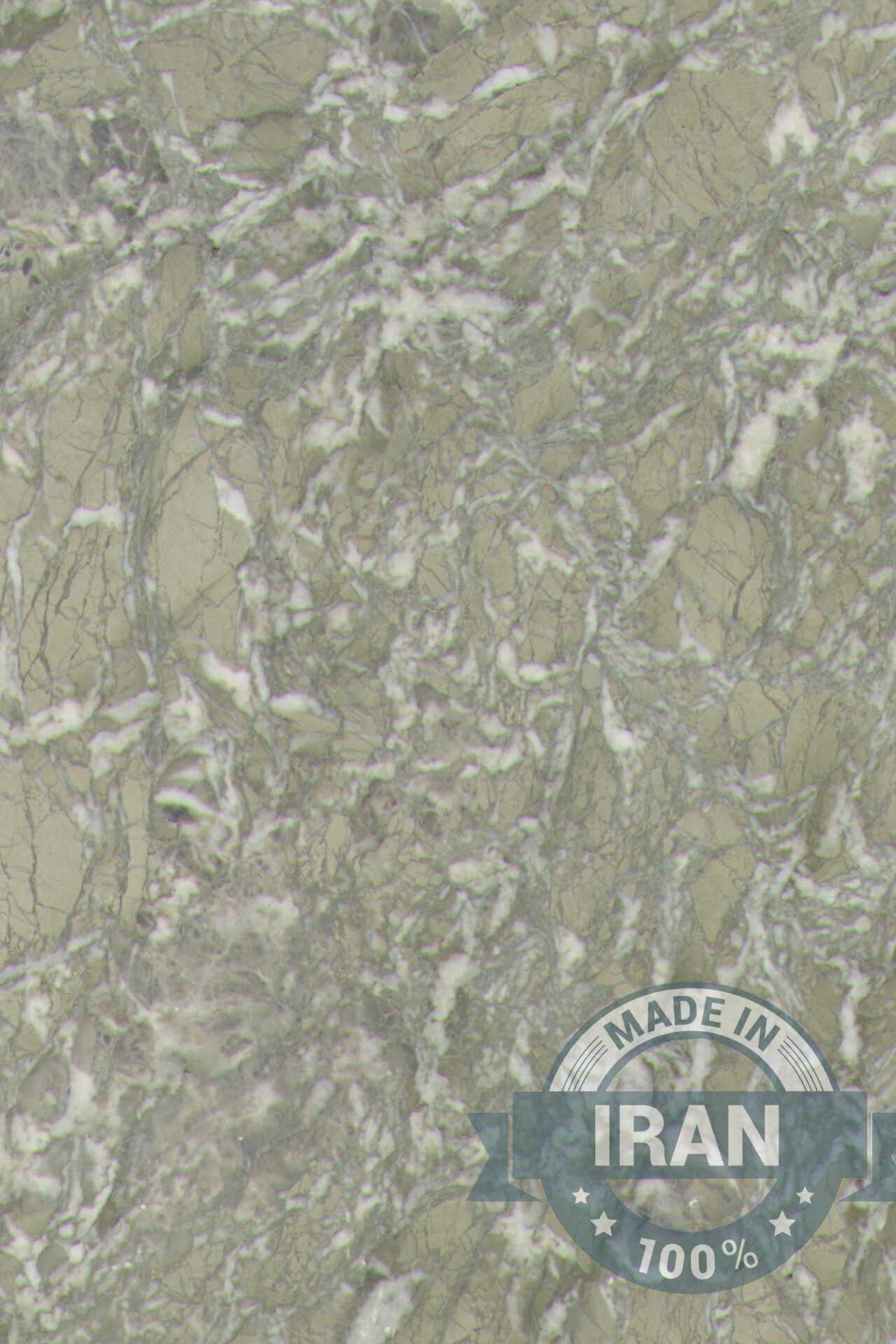

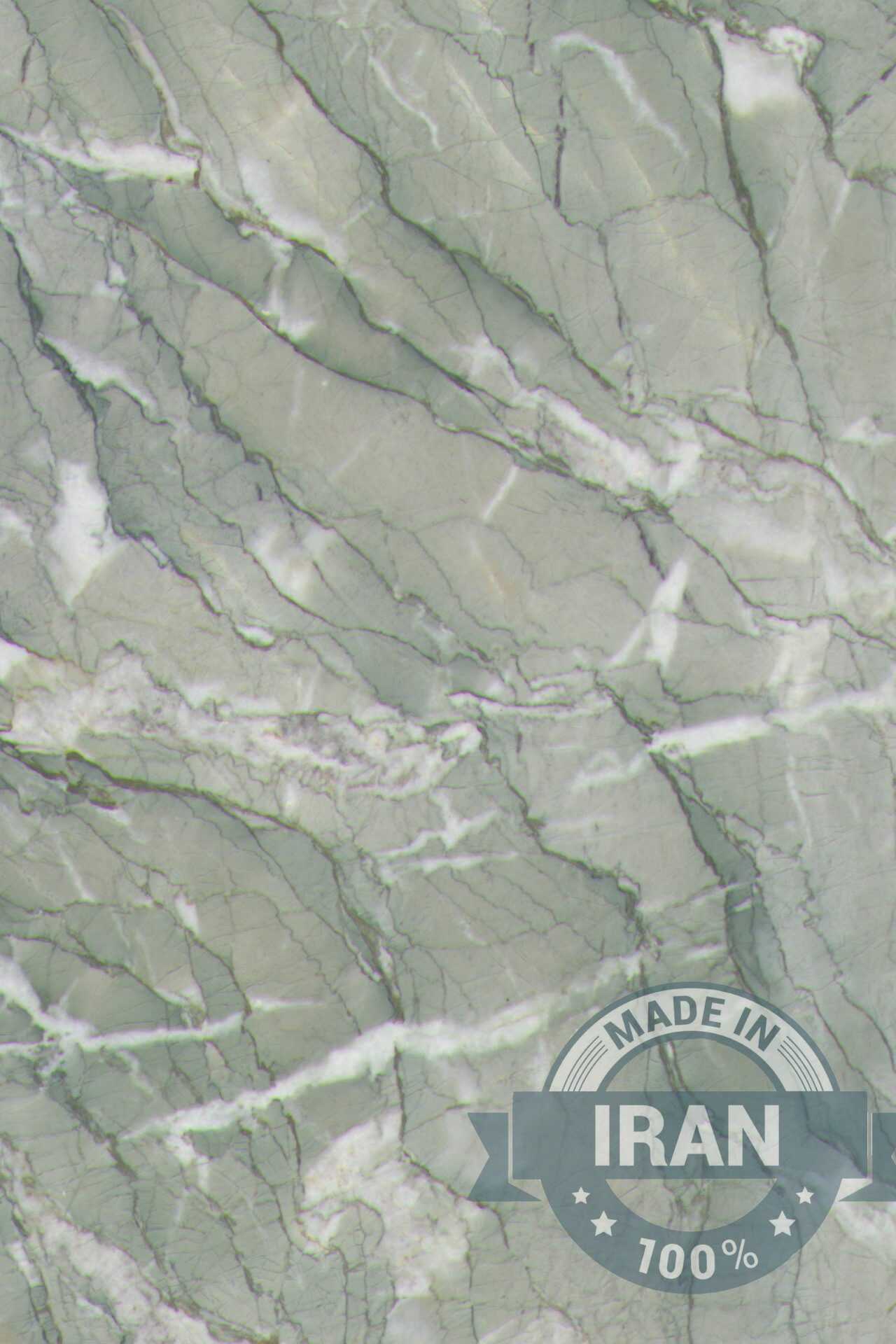

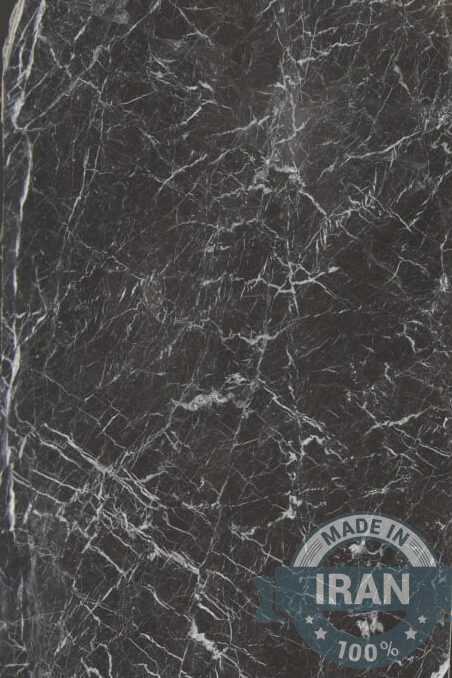

3. Product Range – Colors, Finishes, and Grades

We supply a comprehensive selection of marble types suitable for wholesale distribution. Each variety comes with customizable thickness, surface finish, and cutting options.

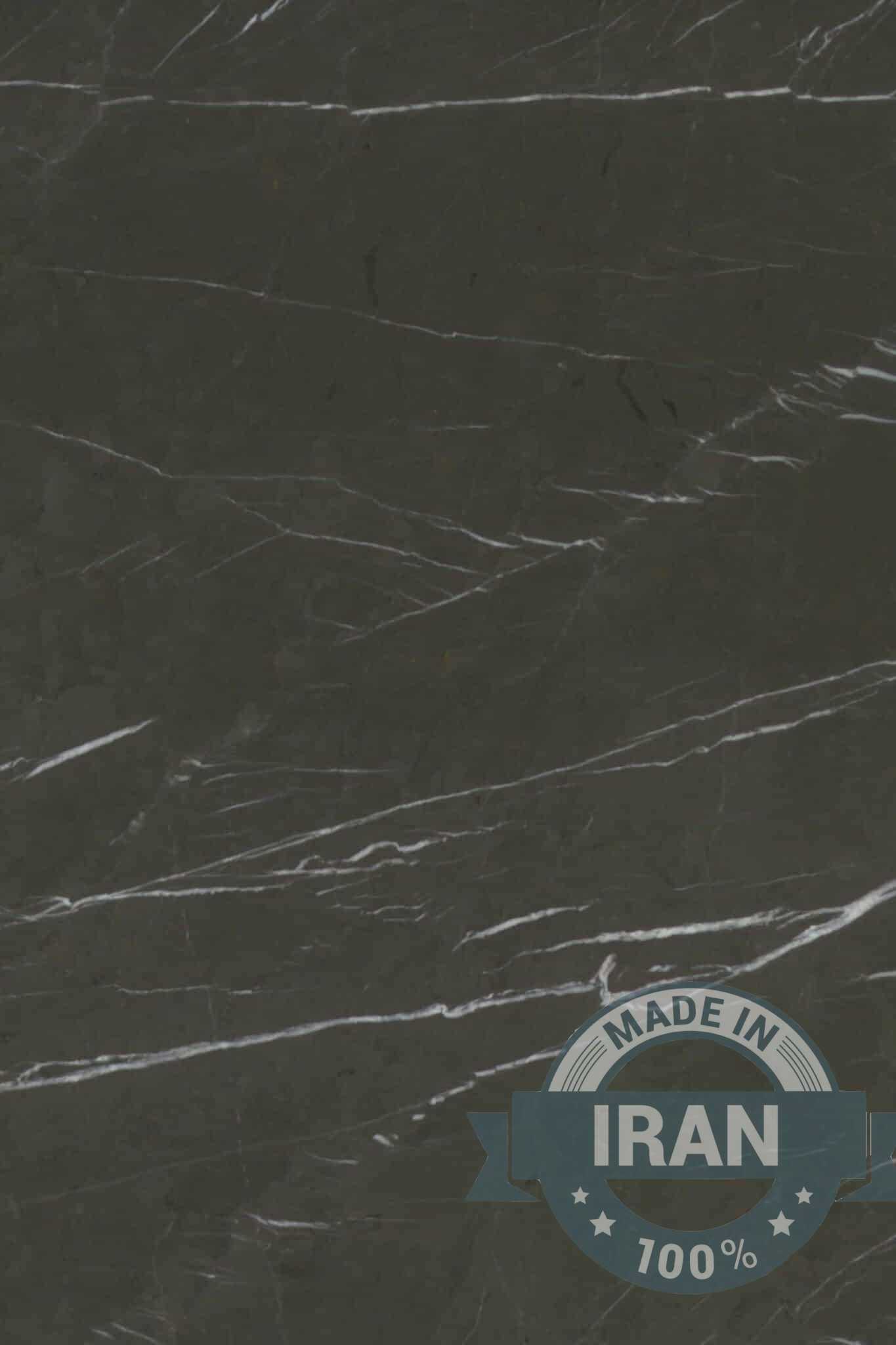

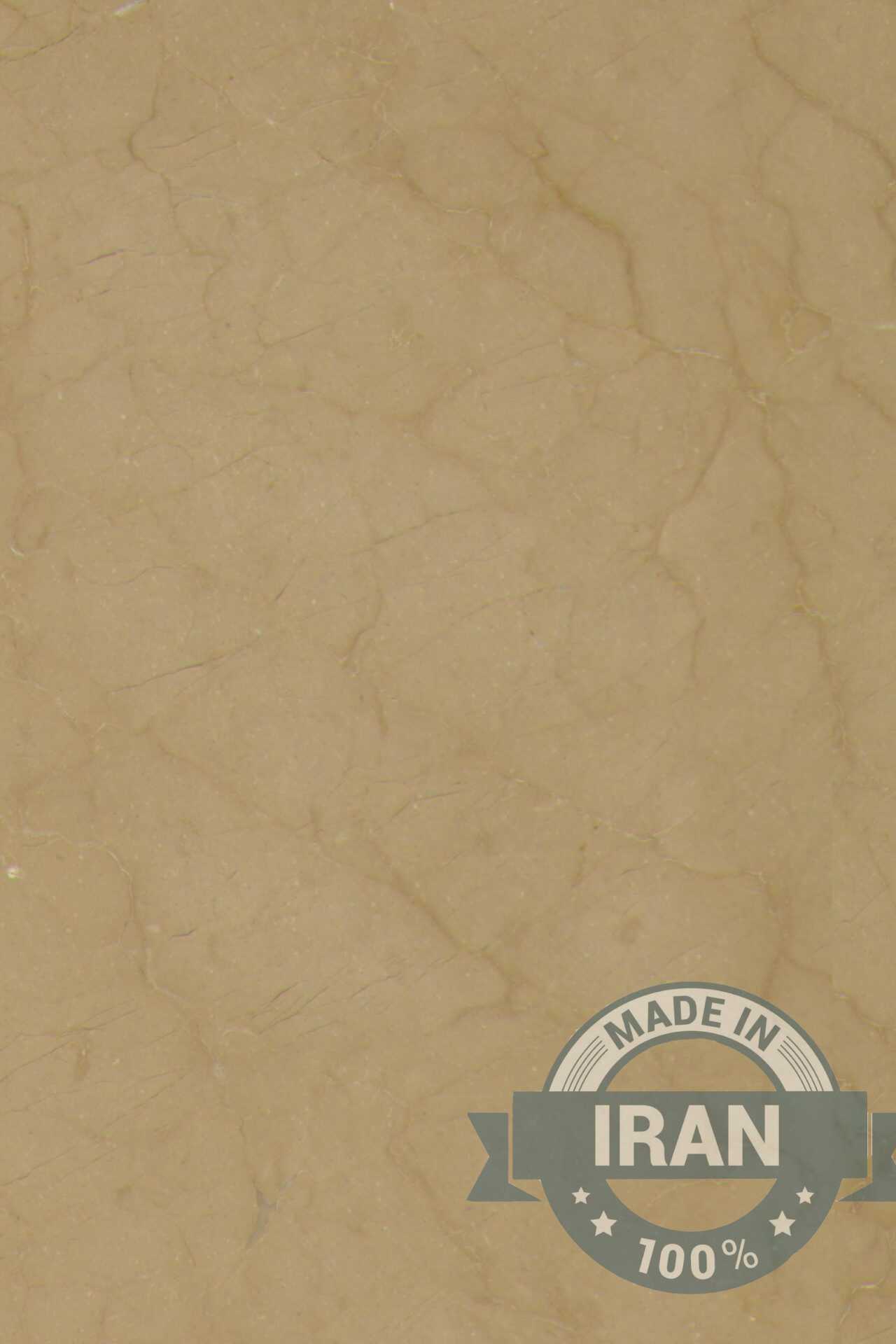

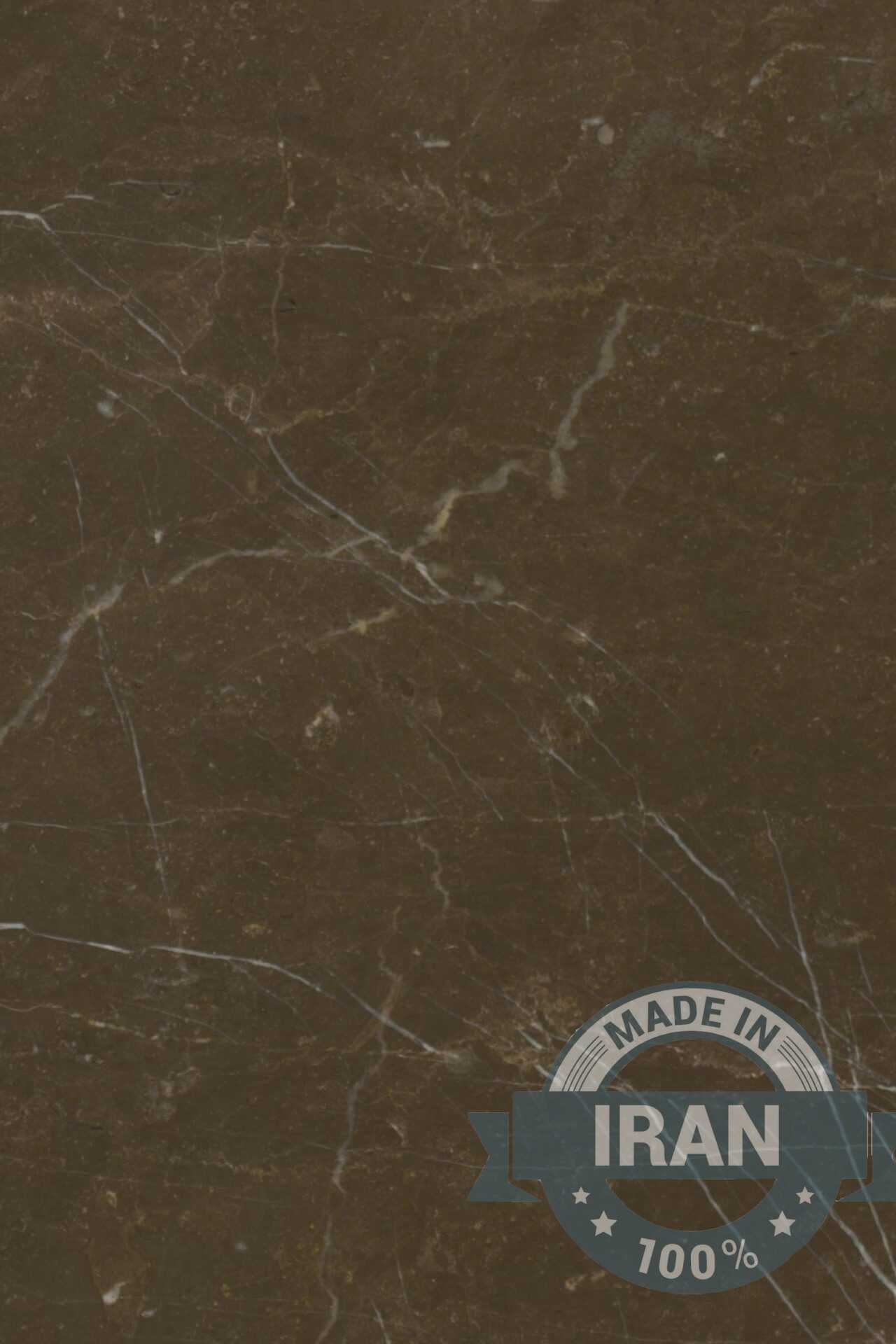

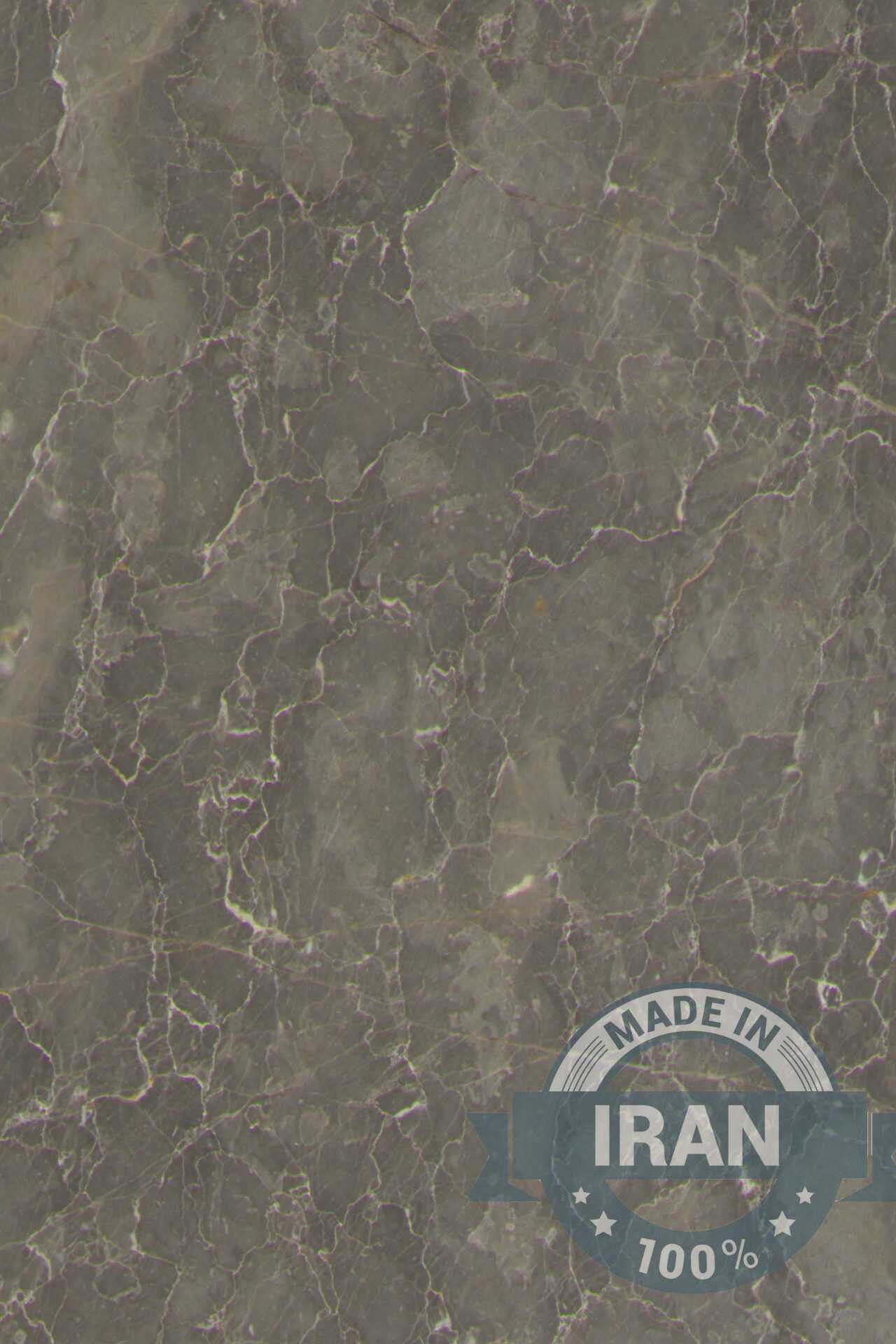

🔹 Common Colors & Finishes

| Color | Finish | Description | Typical Use |

|---|---|---|---|

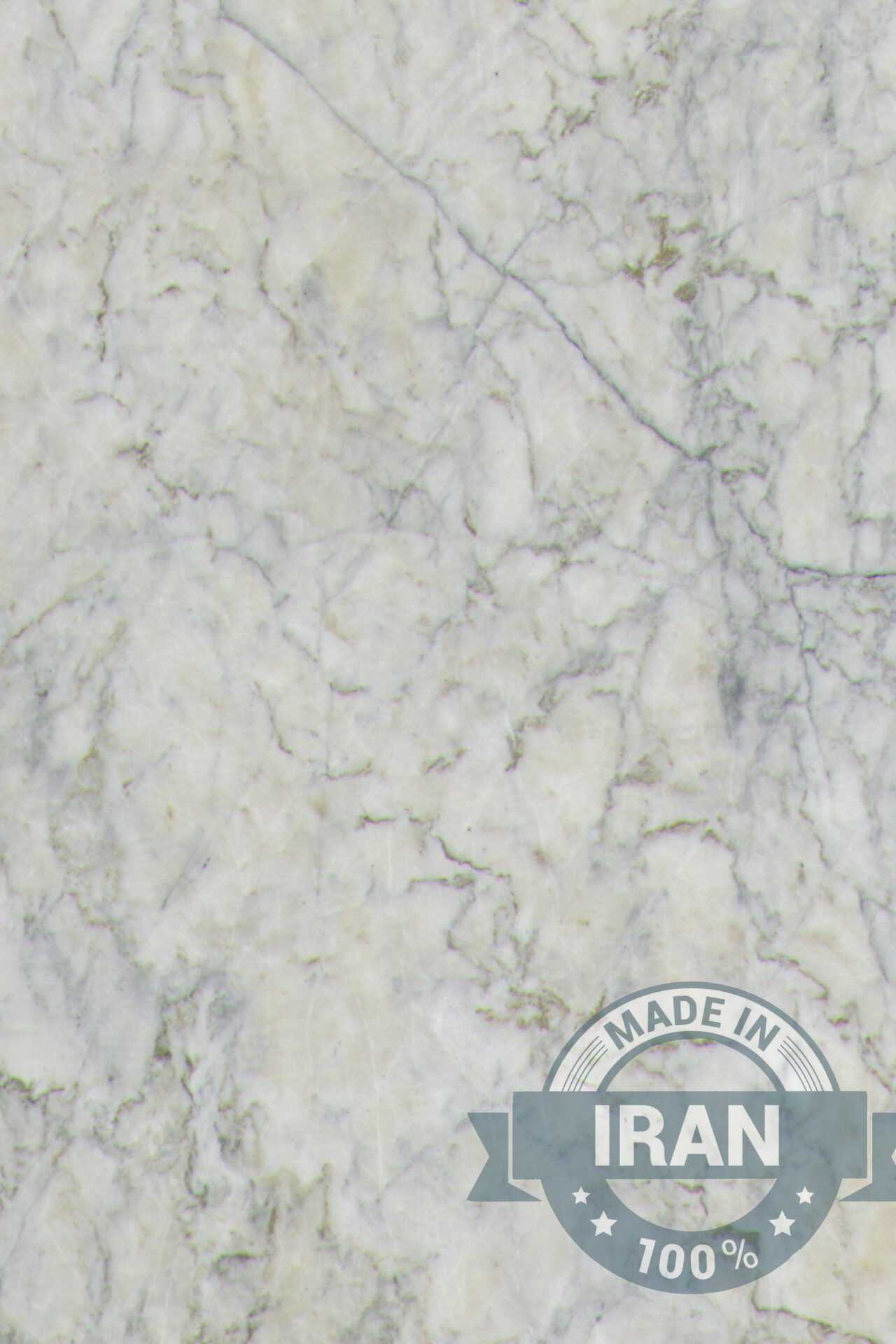

| White Marble | Polished / Honed | Classic bright tone with subtle veins | Flooring, luxury interiors |

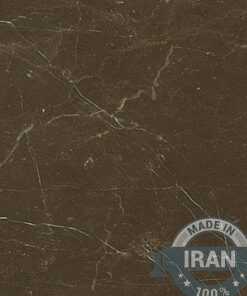

| Beige Marble | Honed / Brushed | Warm neutral hue | Commercial buildings |

| Grey Marble | Polished / Sand-blasted | Modern architectural projects | Walls, exteriors |

| Black Marble | Mirror-polished | High-contrast elegance | Feature walls, counters |

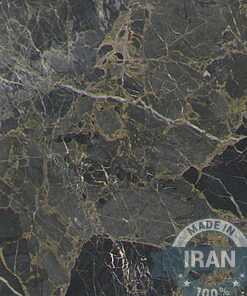

| Multicolor Marble | Mixed finish | Dramatic patterns and veining | Art walls, decorative pieces |

🔹 Surface Finishes Explained

-

Polished: mirror-like shine emphasizing natural color depth.

-

Honed: matte, non-reflective finish for contemporary aesthetics.

-

Brushed / Antique: slightly textured surface enhancing grip.

-

Tumbled: aged appearance ideal for rustic or classical designs.

-

Sand-blasted: rougher texture for outdoor flooring or façades.

4. Technical Specifications

| Property | Specification | Testing Standard |

|---|---|---|

| Density | 2.6 – 2.8 g/cm³ | ASTM C97 / EN 14617 |

| Water Absorption | < 0.5 % | ASTM C97 |

| Compressive Strength | 80 – 120 MPa | ASTM C170 |

| Flexural Strength | 10 – 16 MPa | EN 12372 |

| Abrasion Resistance | High | EN 14157 |

| Available Thickness | 20 mm / 30 mm (custom 20–60 mm) | — |

| Slab Size Range | 600×600 mm up to 1200×2400 mm | — |

| Finish Options | Polished, Honed, Brushed, Tumbled | — |

| Moisture Expansion | Negligible | — |

5. Quality Control & Manufacturing Process

All marble slabs undergo multi-stage inspection:

-

Raw block selection: verified for uniform color and minimal fissures.

-

Cutting and slab calibration: performed on diamond gang saws.

-

Surface finishing: polishing up to 80 – 95 gloss units.

-

Edge trimming & labeling: consistent sizing tolerance ±1 mm.

-

Final inspection & packaging: random sampling for water absorption and compression testing.

Every shipment is certified with inspection reports, packing lists, and labeling corresponding to international export documentation. Suppliers adhere to ISO 9001 and CE quality systems to guarantee repeatable performance in bulk deliveries.

6. Packaging, MOQ & Logistics

| Item | Detail |

|---|---|

| MOQ (Minimum Order Quantity) | One × 20 ft container (≈ 400 – 450 m²) |

| Packaging | Fumigated wooden crates, waterproof film, foam separators |

| Container Load | ~24 tons (slabs or cut-to-size tiles) |

| Shipping Terms | FOB / CIF / EXW (sea or multimodal transport) |

| Lead Time | 30 – 45 days after order confirmation |

| Documentation | Packing list, Invoice, Certificate of Origin, Inspection Report |

All crates are reinforced with metal straps for maritime shipping. Pallet labeling includes product code, batch, and finish details for warehouse traceability.

💬 Price on Request:

To receive detailed pricing, MOQ adjustments, and freight quotations, please message us on WhatsApp or submit the Request Quote form on our marketplace. Our export support team responds within 24 hours.

7. Sustainability & Environmental Responsibility

Modern construction increasingly values sustainability. Our marble suppliers utilize:

-

Recycling of water and slurry in cutting facilities.

-

Energy-efficient machinery reducing CO₂ output.

-

Waste-management programs converting remnants into aggregates.

-

Compliance with EU REACH and Green Building Standards where applicable.

Marble is a natural, 100 % recyclable material that can be repurposed and re-finished over time. Its long lifespan supports environmentally responsible building practices.

8. Commercial Advantages for Buyers

-

Direct sourcing from verified stone producers

-

Competitive wholesale pricing without intermediaries

-

Flexible MOQ for project-based orders

-

Dedicated export logistics and customs support

-

Real-time communication via WhatsApp, email, or platform dashboard

-

Ability to combine multiple stone types (marble + travertine + limestone) in one shipment

We aim to simplify international stone procurement by acting as your one-stop marketplace for natural stone sourcing.

9. Frequently Asked Questions (FAQ)

Yes. Mixed varieties are available per container as long as each type meets MOQ for packaging safety.

Polished marble has a glossy reflective surface; honed marble is smooth but matte, preferred for modern or low-glare interiors.

Absolutely. Small samples can be sent for evaluation before order confirmation.

Each slab is individually separated with foam sheets and plastic film, packed in fumigated wooden crates reinforced with metal bands.

Standard terms include 30 % deposit and 70 % before shipment by T/T, or LC at sight for large contracts.

Yes, third-party inspections are welcome prior to loading.

We deliver worldwide via sea freight from major ports; air freight available for urgent orders.

Usually 30 – 45 days from confirmed deposit and specification approval.

Send your detailed requirements (sizes, finishes, quantity, destination port) through our Quote Form or WhatsApp channel; our sales engineers will prepare a customized offer within 24 hours. Q1 – Can I purchase mixed colors or finishes in one container?

Q2 – What is the difference between polished and honed marble?

Q3 – Do you provide samples for color approval?

Q4 – How are slabs protected during shipment?

Q5 – What are your payment terms?

Q6 – Can you handle inspection by third parties (SGS, BV)?

Q7 – Do you ship globally?

Q8 – What is the estimated delivery time?

Q9 – How can I get an official quotation?

Reviews

There are no reviews yet.